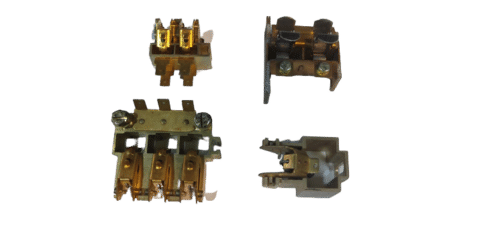

Slip Ring Unit

Product Details:

- Product Type Slip Ring Unit

- Application For Electromechanical System

- Rated Voltage 220-440 Volt (V)

- Color Red and Silver

- Weight 20-150 Grams (g)

- Click to View more

Slip Ring Unit Price And Quantity

- 1 Piece

- 1000 INR/Piece

Slip Ring Unit Product Specifications

- For Electromechanical System

- 220-440 Volt (V)

- Slip Ring Unit

- Red and Silver

- 20-150 Grams (g)

Slip Ring Unit Trade Information

- Cash Advance (CA) Telegraphic Transfer (T/T) Cash in Advance (CID)

- 1 Piece Per Day

- 1 Days

- Carton Box

- All India

Product Description

Slip Ring Units

A slip ring makes an electric connection via a rotating assembly. There is rotary electrical interfaces, electrical rotary joints or rotating electrical connectors. We keep up with Slip Ring Units that are well integrated, compact and reliable. Also, we offer a range of shapes, sizes and specifications to suit any specific application. We serve for commercial, industrial, power and other sectors. Our well designed Slip Ring Units meet the requirements of todays stringent environments. We use the latest technology and best inputs to guarantee reliable connection and long-term operation. We help reduce downtime as well as maintenance costs.

Our Slip Ring is intensively known as an electromechanical instrument, which permits the transmission of electrical signals and power from a non-moving to a turning structure. It can be utilized as a part of any electromechanical arrangement that demands unreasonable, irregular or consistent turn while transmitting data and power. This can enhance mechanical execution, disentangle system working as well as dispose of harm inclined wires hanging or fixed from moveable joints.

These slip rings help the exchange of signal circuits or electric power over a pivoting surface, for example, those discover in radar radio wires, periscopes, space satellites, gun turrets as well as electro-optic detector gimbals. The sliding connection is built up by a brush, which presses in opposite direction of a metal ring. Further, the brush can resemble a brush created using metal strands, however more regularly it would seem that a spring or a solitary wire with a stack of material appended to the end, which connects the ring. Our Slip Rings capacity is to make at least one constant electrical contacts from points in a non-moving unit to ends in a turning area.

Slip Ring Maintenance

Appropriate and regular handling is central for the service life as well as protection of our slip ring. Complete information will be offered in the handling manual offered with the item itself.

Testing

Every unit is examined before delivery, this comprises yet is not constrained to, progression, protection resistance, dielectric quality, rotational and torque tests.

The electric circuits are equipped for direct error surges and levels without burden. Our slip rings, brush terminal and in addition, terminal outlines are well demonstrated.

Delivery

An extensive instruction and handling manual is provided with every unit and incorporates a Trolex Certificate of Declaration as well as Conformity of Incorporation. Furthermore, all Trolex Engineering items are painstakingly packed for security amid transport.

Advantage:

- Less torque limit system torque budget

- Tight packing to suit in the most requesting space

- Seamless running

- Low electrical sound

- Fast shipment per customers critical demand

- High data transmission exchange capacity

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Slip Ring' category

|

PERFECT ELECTRIC CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |